Setting up a solar investment modules production plant would be a great opportunity for investors focusing developing countries.

Solar Investment Success Story:

During the year 2013, under a development project, we imported a Solar Modules Production Plant with the capacity of 10 MW per annum from Gobo Solar (China) for Pakistan Council of Renewable Energy Technologies in Islamabad, Pakistan. This plant was installed for a limited production of Hi-Quality PV Modules using Mono Crystalline Solar Cells indigenous produced from 5-inch diameter Silicon ingots. The fulfilling purpose was to dispatch hands on-training to students, technicians and researchers, converting solar cells into solar modules.

Solar Investment Plant cost:

The procurement cost was around USD 2,00,000 with installation, commissioning and operational training by two experts flying directly from China.

Solar Investment Plant cost will include:

The plant comprises of a total of 82 parts including: Two Class-AAA Solar Cell Testers, Class-AAA Sun Simulator/Solar Module Tester to test against IEC 61215, Electro Luminescence (EL) Tester, Laser Scribing Machine to cut solar cells, 43-feet fully Automatic Laminator for 900 W one go lamination in 16 minute, multiple solder strip cutting machine, Automatic Framing machine, Module repair machine, 125 Welding Templates, Solar Cell Sorter, six welding stations, EVA/TPT cutting table, two observational test tables, modules laying tables, modules carrying trucks, storage racks and so on.

Solar Investment Plant production capacity:

This plant, which is capable of producing 10 MW of solar modules in three shifts (35 workers each), working round the year in 320 days produces 10 million watt.

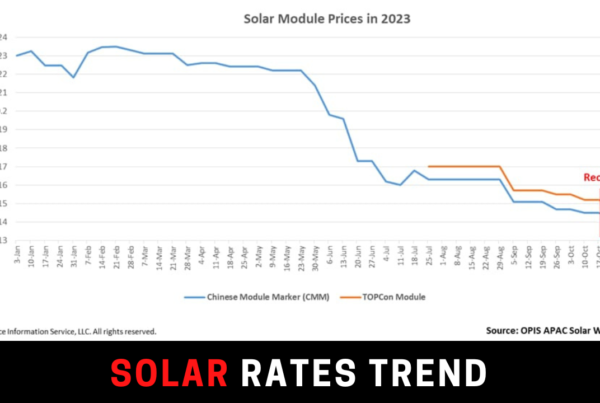

Solar Investment Plant payback time calculated:

If we intended to commercialize eyeing a so-called profit of 2 Cents per Watt, we were aiming at a payback which recovered the cost of the plant in only one year. Likewise, if the profit is adjusted at 4 Cents per watt, the payback will be 6 months.

About the production material:

The materials include the solar cells, soldering strips, bus bars, solar glass, EVA (Ethyl Vinyl Acetate-for transparent binding between solar glass and cells and back sheet ), Tedlar/back sheet, Junction Box/cable/connectors, Framing materials, and other peripherals are available from international market including EU, Argentina, China and Taiwan etc.

Solar Investment Production process:

Where would we source the raw material from:

Regarding provisions of Hi-Quality solar cells, based on my learning from two of the Japan’s APO Study Mission on Photovoltaic Technologies (2013 & 2014), the world leading PV Module manufacturers are also using Taiwan and Chinese made solar cells of 16% to 18% efficient Poly and 18 % to 20% efficient Mono cells to produce 15% to 16% Poly and 16.5% to 18.5% efficient Mono Solar Modules.

At the PCRET we produced 16.0 % to 17.2 % Mono Modules using MASRROCK, Chinese 18.4% Mono Crystalline cells. These cells were tested on our class-AAA cell tester and found well with in + 0.0 2 % of 18.4% stated efficiency.

Some concluding remarks about precedent setting with Solar Investment:

Now sharing my experience, there are many other inputs like utility requirements including power, water supply, air pressure, vacuum and environmental control etc. A maximum of 100 kW 3 Phase 380 Vac, 50 Hz /220 Vac 50 Hz power is required to run this 10 MW production plant. A detailed list of parts and materials and total cost per watt of Hi-Quality Solar Module (15% to 17% Poly and 16% to 17.2%) can be shared to individual reader for their interest in this production business.

What we can offer:

Wehave some exclusive offer from Gobo Solar which we would like to extend at a small consultancy fee sharing the feasibility for the same 10 MW Solar Modules Production Plant. At a reasonably low price (as low as 70 per cent of the shared cost): under my consultancy at Zorays Solar (a promoter of GOBO Solar in Middle East) we extend great promises on not only help you setting up but dispatching all the essential training for running such a commercial plant. On top we adhere to strict quality control for which we will suggest complete testing facility including state-of-the-art Commercial Solar Cell Testers and Commercial Sun Simulator.